Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

Why dairy cows like BOGE’s scroll compressors

CUSTOMER

PROJECT

PROJECT INFOS

With milking, nothing is more important than hygiene …

The challenge

The barn environment makes complex demands on a compressed air system – not only because it involves milk, a food product. Oil-free compressed air is clearly a must, but what about the refrigeration dryers that remove the moisture from compressed air? The copper they contain is at risk from the ammonia in the air within the barn. And ultimately there is also a serious space problem when installing the container.

The BOGE solution

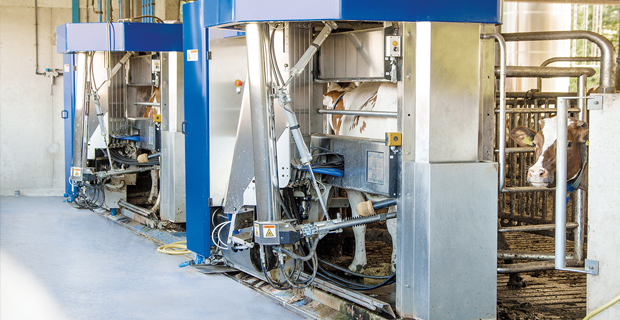

Taute uses one oil-free BOGE scroll compressor of type EO 4 (eccentric oil-free, 4 kW) for each of up to three milking robots, for the many compressed-air assisted production processes in milking. To prevent damage and breakdowns caused by corrosion, the refrigeration dryer module is simply placed in a separate area. And to solve the space problem, a considerably shortened base container was exclusively produced.

The result

A customised compressed air station that produces completely oil-free compressed air safely and efficiently, and which serves as a model for all other milking robots at Taute.